Welcome to Gemuani, where we provide healthy and delicious fruits and vegetables.

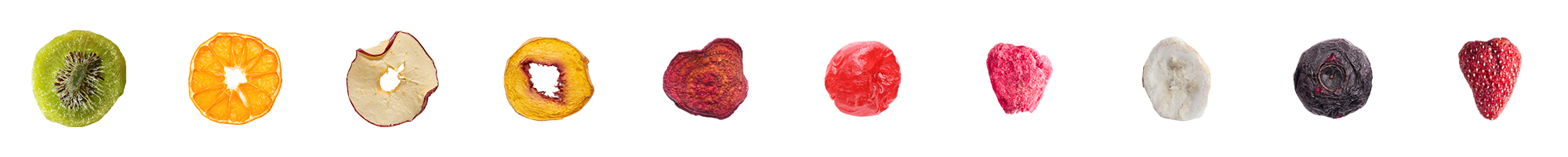

Our factory and farm is nestled in Western Georgia, between the majestic Caucasus Mountains and the shimmering Black Sea. With 25 hectares of orchards kiwifruits, peach, persimmon hazelnuts, processed in our state-of-the-art plant. For production we use only 100% natural fruits, berries, vegetables, which are mainly grown in Georgia, with the exception of some exotic fruits. We use the unique nature of Georgia, wild, endogenous and bio products with gratitude and care. Our consumers from different countries have the opportunity to try the unique taste of unique varieties growing in Georgia: kiwi, feijoa, sea buckthorn, mandarin, wild tangerine (fortunella), lemon, raspberry, strawberries, raspberries, grapes, tarragon, broccoli, basil, garlic... Our freeze-drying process removes 97% of moisture from fresh fruits and vegetables, retaining up to 98% of vitamins and nutrients. This all-natural technique preserves the quality, taste of our products and people world wide have the opportunity to try the unique taste of unique varieties growing in Georgia.

Since our founding in 2011, we've achieved significant milestones. We earned Global GAP certification in 2015, launched our freeze-drying factory in 2017, and obtained IFS certifications and FDA registration. We were recognized as a "golden supplier" for Nestle in 2020 and named the "N1 Golden Brand" in Georgia's market. We export our products globally.

All-natural process create freeze-dried fruit snacks without additives or preservatives, perfect for health-conscious consumers.

The company uses freeze-drying to preserve fruits and vegetables. Thus, recognizing the need for constant innovation and expansion and the growing demand for healthier fruits and vegetables, Gemuani developed and opened a state- of - the - art freeze- drying facility with funding from the Agency for Agricultural Project Management(APMA) of the Ministry of Agriculture, Ministry of Economy and Sustainable Development with USAID support through the REAP program.

Freeze drying is an all-natural process that removes 97% of moisture from fresh fruits and vegetables and retains up to 98% of the vitamins and nutrients found in fresh fruit. Raw materials are deep-frozen, then transferred to a freeze-drying chamber where moisture, which quickly transforms into a gaseous form, is removed under low pressure without the use of heat.

Freeze drying - technically known as lyophilization, lyophilization, or cryo-drying - is a dehydration process commonly used to preserve perishable materials or to facilitate their transport.

The freeze-drying process was invented in 1906 in Paris. In 1911, a freeze-drying method was developed to preserve the live rabies virus, which eventually led to the creation of the first rabies vaccine. Modern freeze drying was developed during World War II to preserve blood serum sent to Europe from the United States to treat the wounded.

Soon thereafter, the freeze drying process was applied to penicillin and bones, and lyophilization became recognized as an important method for preserving biological substances. Since then, freeze drying has been used as a method for preserving or processing a wide variety of products.

Our freeze-drying process removes 97% of moisture from fresh fruits and vegetables, retaining up to 98% of vitamins, bio-active ingredients and nutrients. This all-natural technique preserves the quality, taste of our products and people world wide have the opportunity to try the unique taste of unique varieties growing in Georgia.